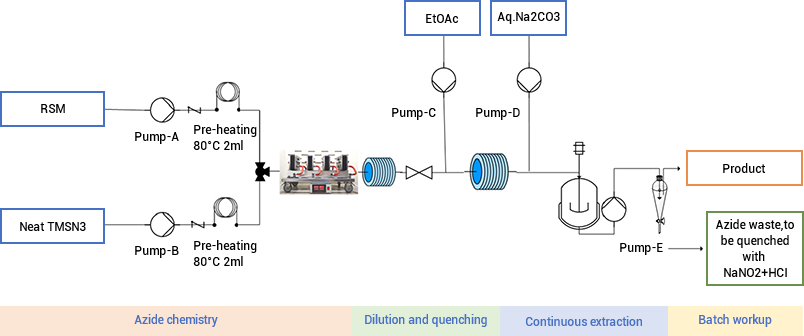

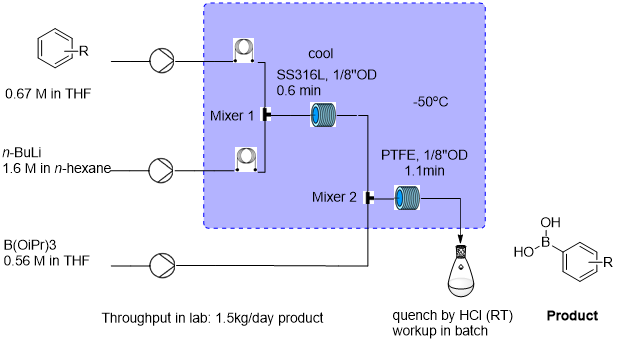

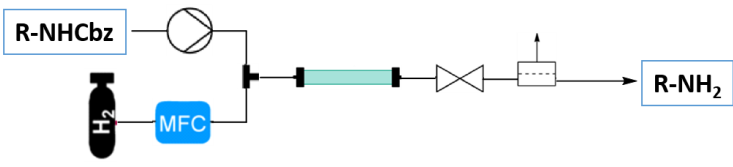

Langhua Pharmaceutical's continuous flow process platform is equipped with a variety of modular equipment, including different kinds of pumps, gas or liquid mass flow controllers, (MFC), mixers, coil reactors made of stainless steel or PFA, microchannel reactors made of silicon carbide (SiC), packed bed reactors (PBR) , continuous stirred tank reactors (CSTR), back pressure valves (BPR), gas liquid separators (LGS), temperature control units (TCU), etc. Based on the process needs, those equipment could be flexibly assembled into a experiment apparatus for development and optimization of continuous flow process in lab. With automatic hydrogenator, Langhua could screen the catalysis and reaction conditions efficiently for hydrogenation. Additionally, the platform includes the commercial-scale microchannel continuous flow reactor with the production capacity of thousands of tons per annum, which could meet the larger-scale production needs.

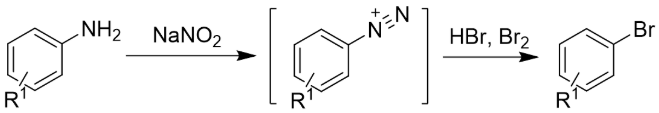

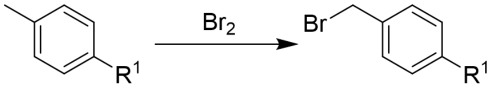

Langhua has successfully completed continuous flow process development for organolithium reaction, oxidation, diazotization, azide reaction, nitration, hydrogenation, etc, of which the apparatus flux capability could reach 1-50 kg per day. Langhua could provide service in the design of continuous process routes, continuous flow process development, reactor design, and the commercial production implementation of continuous flow process.